In 2005, the movie Serenity was released to theaters. It was written and directed by Joss Whedon (of recent Marvel Avengers fame) and was the continuation of the cancelled-far-too-soon TV series Firefly.

Serenity was an awesome movie, and contains one of my favorite lines of theatrical dialog ever. It just so happens that this dialog also describes perfectly how today’s day went:

So, where to start? Let’s go back to last Sunday when I discovered my gas, temperature and oil pressure gauges weren’t working.

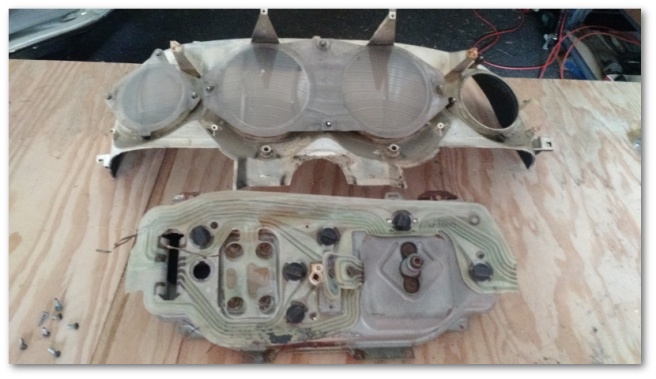

That night, I took the instrument cluster totally apart. I figured if there was something wrong with it and if I had to take it apart I might as well take advantage of the opportunity to make a few things better.

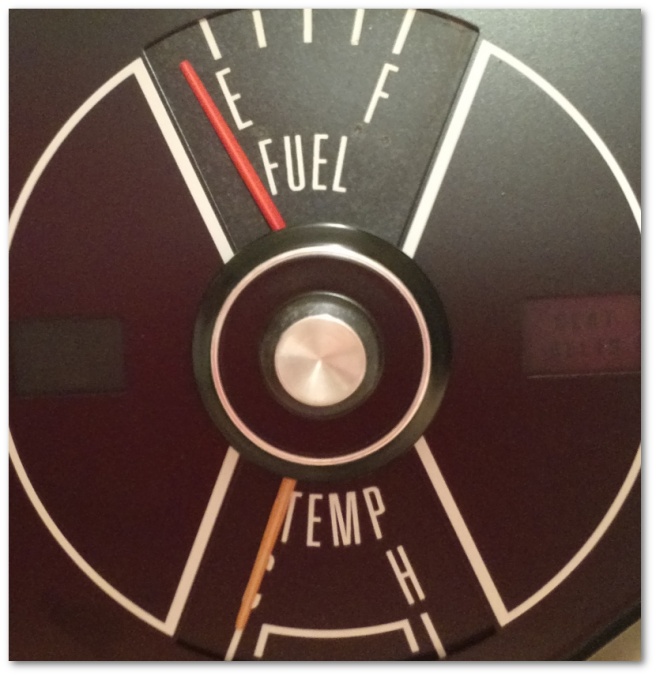

Last week, after I installed the salvage yard gas gauge I discovered that the needle had a slightly different color orange than my original temperature gauge’s needle:

My first attempt to make this better was to simply use the temperature gage from the salvage yard instrument cluster as well. This gave me consistently colored needles, but when you took a close look, neither salvage-yard gauge face was in the best of shape.

I tried cleaning the face plates, but the problem wasn’t dirt or grime. The surface was pitted and starting to corrode so there wasn’t much I could really do. Unfortunately, these gauges are 70 dollars each. I really didn’t want to spend that if I didn’t have to – especially since it appeared as though both gauges were functional.

So I did what any self-respecting engineer would do when presented with a similar problem.

I took them apart:

In the end, I used the face plates from my Mustang with the actual gauge guts from the salvage yard instrument cluster. From what I’ve read, the gauge guts are all interchangeable between oil, temperature and fuel so I could have used any of the gauges in any place. However, as it turned out I used the salvage yard gauges for their original jobs. In the end, I had the best of all worlds – nice gauge faces and consistently colored needles.

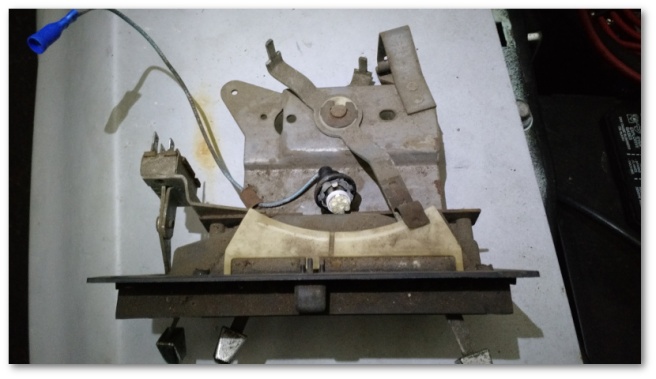

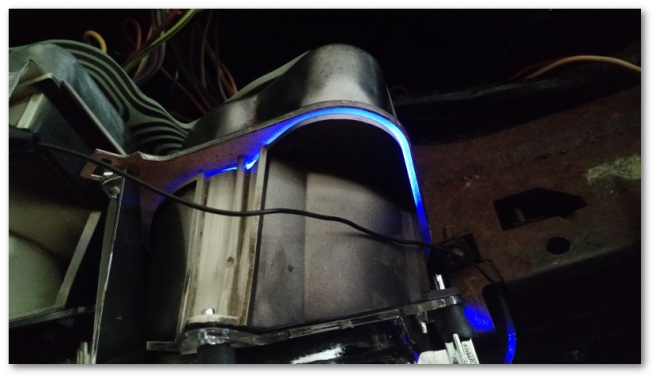

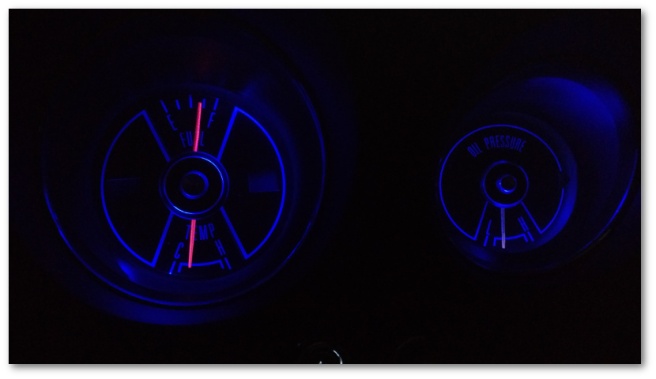

I also took the opportunity to fix a light-leaking problem around the oil pressure gauge:

When I put the instrument cluster together, I must have let the gauge slip internally and it ended up not quite aligning with the cluster and leaking light out. It wasn’t a big deal but again since I had the cluster apart it was worth fixing.

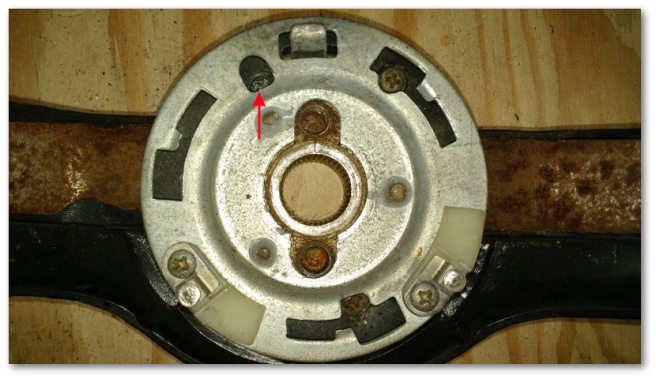

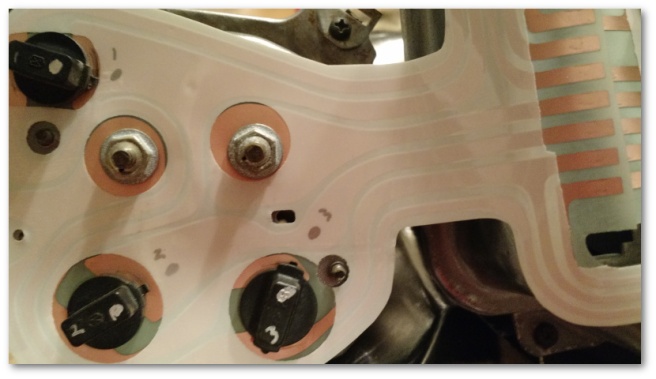

Putting the lights on the instrument cluster was much easier this time thanks to a great suggestion by my lovely wife. After listening to me grouse about having to use trial and error to get the lights installed right, she made the brilliant suggestion to label each bulb and put an indicator on the bulb housing and circuit board that would indicate how the bulb should be installed:

With this set up, the lights no longer presented a problem during installation. After I got the instrument cluster all put back together, I bench tested it.

And the gauges still didn’t work.

After a few minutes of pouting and a minor temper-tantrum, I got to work figuring out why. The gauges themselves worked individually when I tested them, so why didn’t they work when they were installed inside the instrument cluster?

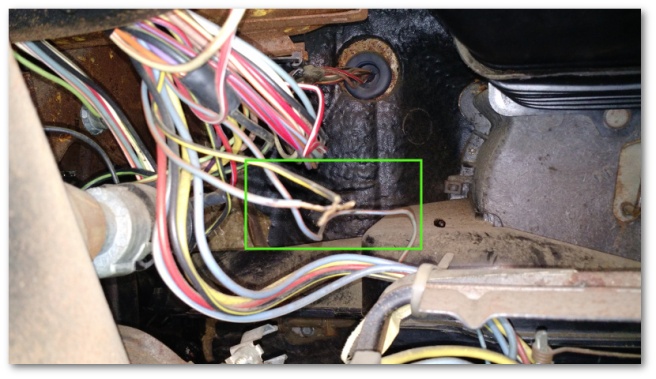

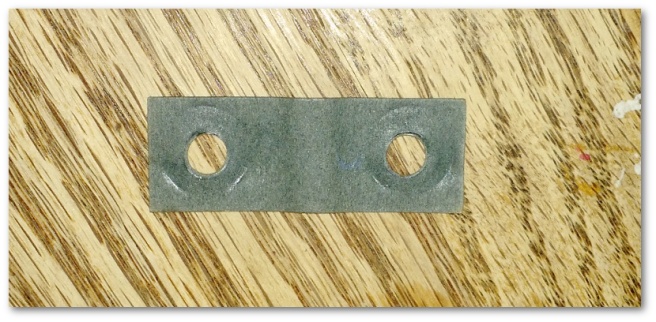

As it turns out, it was this little guy’s fault:

That’s the insulator for the fuel gauge that was installed between the metal instrument cluster housing and the circuit board. This insulator serves two purposes:

- To make sure that the circuit board isn’t grounded by the fasteners attaching to the gauge

- To keep the metal gauge posts centered and not grounded to the instrument cluster housing

The insulator above failed job #2 and grounded the fuel gauge. In doing so, it also grounded all of the other gauges – which was a nice little trick.

So, after taking the cluster apart for the third time and fixing this little problem I bench tested it again. Finally, all of the gauges pegged when I touched their output post to ground and all of the lights lit up when I applied power at the appropriate terminal.

The instrument cluster was tested and as ready as it was going to get.

Which brings us to today and things not going as planned. The &*(^$^&*&^ gauges still didn’t work. I took a long walk.

To describe how I debugged the problem, I first need to explain how these gauges work.

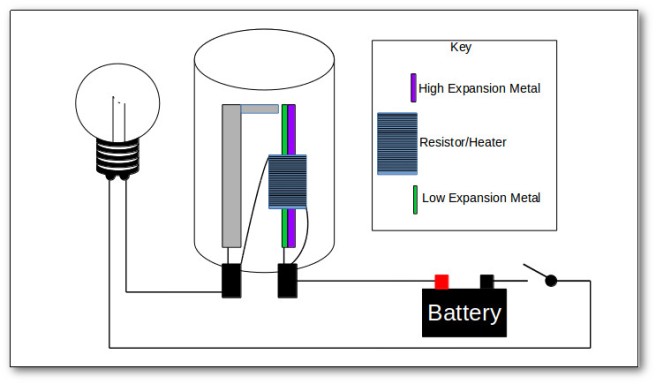

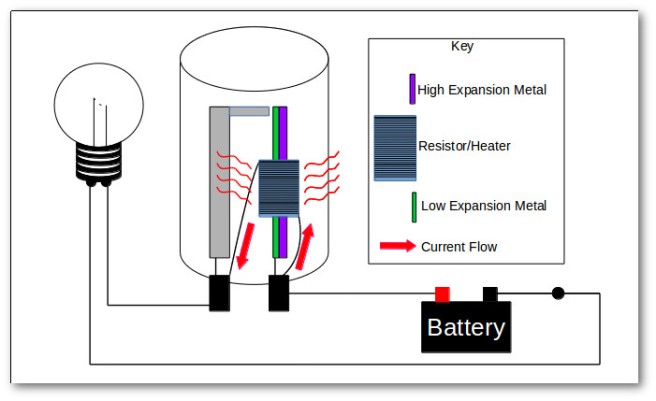

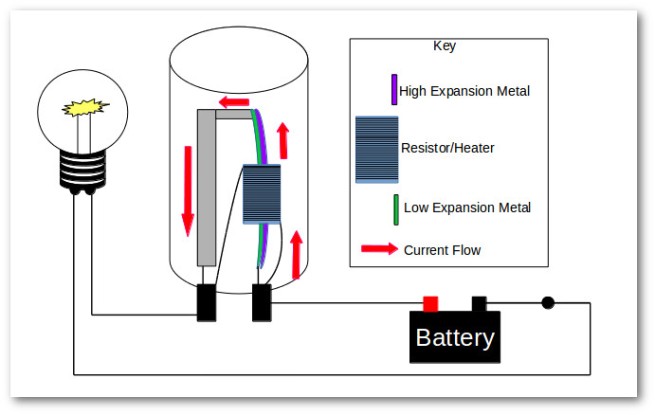

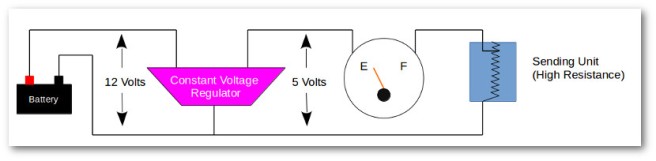

In 1956, Ford started using 12 volt electrical systems instead of the 6 volt systems they had historically used. However, their car’s gauges still used 6 volts – presumably because they had millions of gauges lying around and didn’t want them to go to waste. To get the correct voltage for the gauges, a “constant voltage regulator” was designed that would step down the voltage from 12 volts to 6 volts.

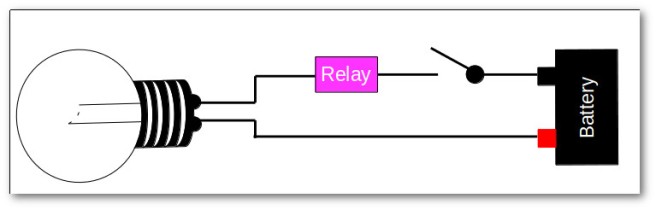

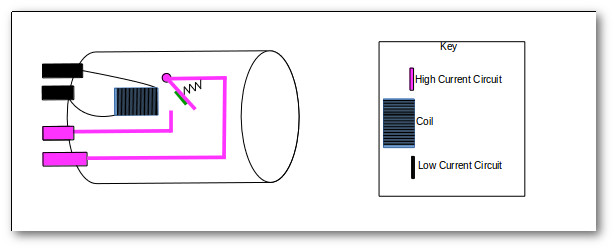

In 1969, this constant voltage regulator worked very much like the thermal relays I described in a previous post. It would oscillate between 0 and 12 volts as the relay inside it actuated and connected/broke the circuit. This oscillation would “average out” to 6 volts and make the gauges happy.

During my debugging, I discovered that today’s constant voltage regulators are solid state and provide a steady voltage that does not oscillate. This constant voltage is then applied directly to the gauge which is wired in series with a sending unit.

The sending unit is essentially a resistor that varies in resistive strength depending on some input or another. In the case of the fuel sending unit, it varies depending on how high the float is:

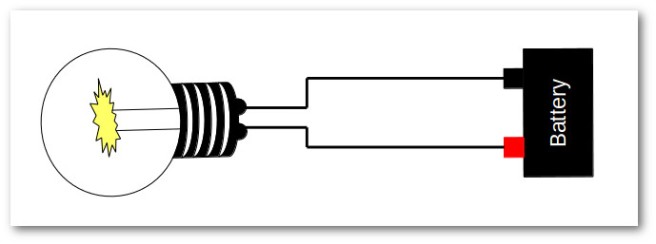

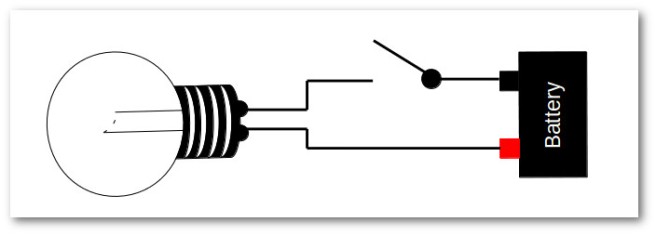

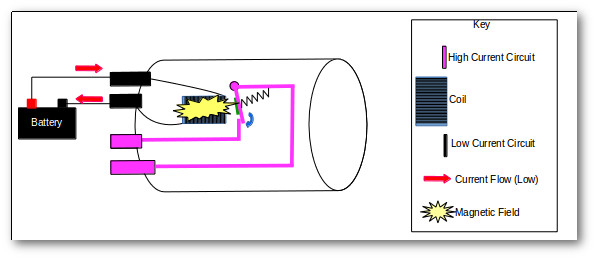

The circuit essentially looks like this:

When the sending unit is in the high-resistance state, very little current flows through the gauge and it reads empty or low.

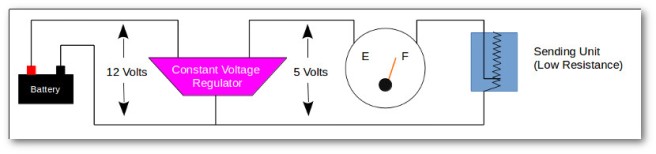

When the sending unit is in the low-resistance state, more current flows through the gauge and it reads higher and higher:

From what I’ve been able to find during my research, the sending unit resistance specification is the following:

78 Ohms – Low peg

65 Ohms – Empty, Low or Cold

39 Ohms – 1/4 scale

24 Ohms – 1/2 scale

15 Ohms – 3/4 scale

10 Ohms – Full, High or Hot

0 Ohms – Top peg

With this knowledge, I set out to debug why the bloody gauges weren’t working.

The first thing I did was to ground both the temperature and oil pressure gauges. This should have (and did) peg both gauges at high. This told me (again) that the wiring from the instrument cluster to the sending units was just fine.

After re-attaching the oil pressure sending unit wire, it decided to start working just fine. Huzzah! One easy fix done just by re-seating a connector.

Unfortunately, the temperature gauge refused to move – even after running the car to its normal operating temperature. At this point, I decided I needed something that would simulate the proper resistance settings for my sending units.

I hadn’t been to a Radio Shack in almost a decade. When I was in college I went there all the time to pick up electrical components for my classes. I decided to give them a try to see if I could find some resistors that would allow me to simulate a sending unit providing data.

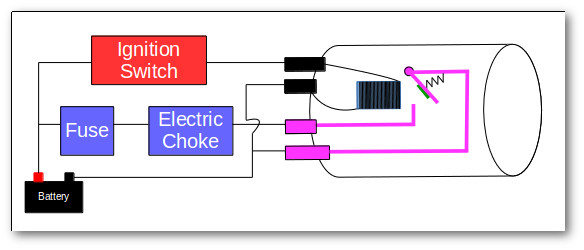

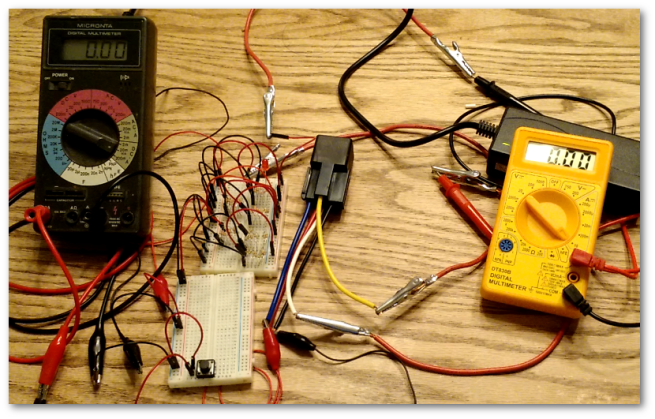

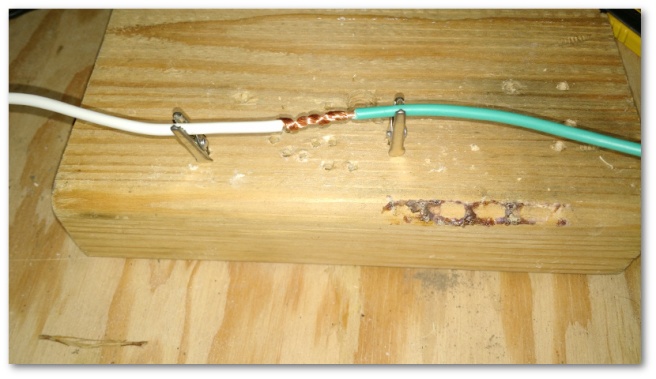

I didn’t find exactly what I wanted, but what I did find was enough to wire up my gas and temperature gauges like this:

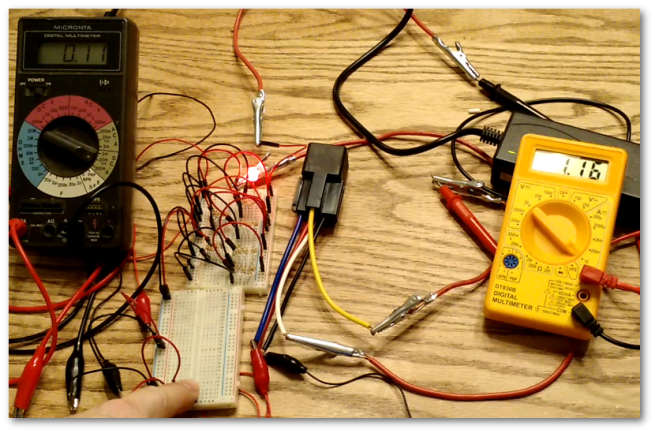

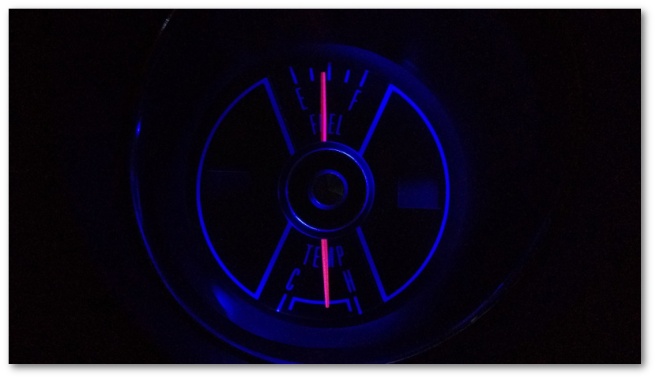

With that circuit, I expected both gauges to read roughly at their mid-point. And sure enough, they did:

And thus began today’s nightmare with sending units.

To start with, I measured the resistance at the terminal of the fuel sending unit. This gave me 80 Ohms – a reading that made sense because I knew there wasn’t much gas in the tank. Filling the tank up though only gave me a reading of 16 Ohms. I have no idea why the sending unit is misbehaving like this. In the video above you can see the unit read 12 Ohms when the float was all the way up. But, for whatever reason today it decided full was equal to 16 Ohms. This meant that the gauge should have read roughly 3/4 of a tank in this state.

And sure enough:

So… crap.

Right now, the gas tank is full of very expensive non-ethanol gas that I don’t want to waste by draining the tank to replace the sending unit. I will fix this eventually, but for right now I’m going to move on and loop back later to fix it.

So, two gauges down – sorta.

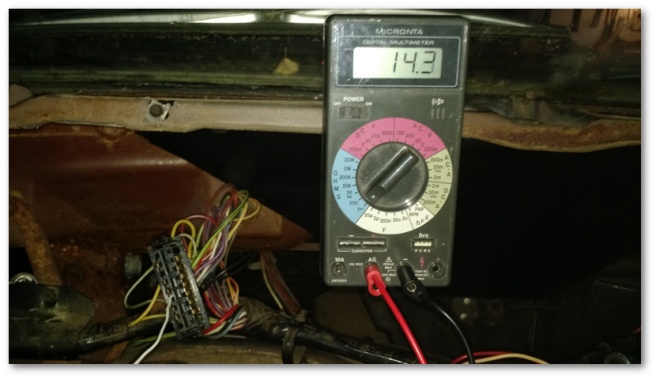

The temperature sending unit proved to be a huge pain in the ass. With the car at running temperature (189 degrees Fahrenheit according to my infra-red thermometer) the sending unit was stuck at 201 Ohms:

Considering the gauges expect at most 80 Ohms it’s no wonder why the temperature gauge would never budge.

After spending the better part of the day debugging this stuff, I was pretty much done with trying to debug this any further so I went down to the parts store and asked for a temperature sending unit for a 1969 Mustang. They had one in stock with the right resistance specifications and I went home with a plan to quickly swap out the part and be done for the day.

In order to install the sending unit, you have to drain the radiator out a bit so that the level of the water is below the hole in the intake manifold the sending unit is installed into. I did this and then took the part out of the box to install.

THE SENDING UNIT DIDN’T FIT INTO THE INTAKE MANIFOLD!!!

It didn’t even come close. The threading for the sending unit was way to large to fit into the itty-bitty little hole I had on my intake manifold. Aghast, I pulled out my original intake manifold to see if I had a sending unit still attached there that I could use. I didn’t (naturally) but pulling the original manifold out served to deepen the mystery even further. The new sending unit fit into my original intake manifold just fine.

Back to the parts store I went.

Me: “This sending unit doesn’t fit. Is there another type for a 69 Mustang?”

Parts Guy: “Uh no. That’s the only one, and it’s the right one for your car”

Me: “You sure?”

Parts Guy (rolling eyes): “Pretty sure, yeah”

So… Crap

At this point, I was out of ideas. It was obvious that the temperature sending unit I had on the car wasn’t giving the gauges the data they needed to display properly. However, I couldn’t replace the sending unit because the new one provided by Mr. Eye-Rolling-Pretty-Sure-That’s-The-Right-Part Guy didn’t fit.

I was about ready to call it a day until I realized something. As it turns out, I don’t actually know that my intake manifold came from a 1969 Mustang.

When we rebuilt the engine, we decided to replace the stock 2 barrel intake manifold with

Ford made the 302 engine for forty-some-odd years. I needed to find out what year and what model so I could get the correct temperature sending unit for it. Easy, right?

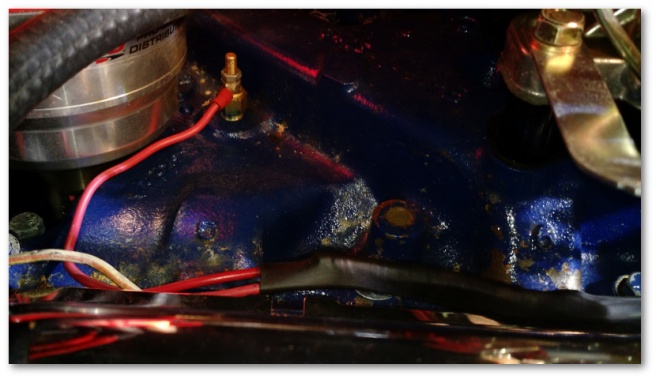

Actually, much to my surprise – yes:

The image above shows the casting part number for my intake manifold. Ford casts these numbers onto many of the parts in their cars to help identify the parts – which was exactly what I needed to do.

A brief google search led me to a site where you can decode these casting numbers. According to that site, here’s the resulting decode of the number above:

C: Car made in the 1960’s

4: Car made in 1964

O: Ford Fairlane

E: Engine Component

So, my intake manifold is from a 1964 Ford Fairlane. Today I learned.

Doing even more research, I learned that around 1966, Ford changed their intake manifolds to have different receptacles for their temperature sending units. This was very promising!

The Napa I normally use was closed, but my neighborhood AutoZone was still open so back to the parts store I went:

Parts Guy: “Hi! What are we working on today?”

Me: “Uh.. umm… A 1964 Ford Fairlane?”

Parts Guy: “What do you need for it?”

Me: “A temperature sending unit”

Parts Guy: “Got one in stock. 11 bucks”

Me: “Sold”

The parts guy didn’t have access to the specification for the sending unit’s resistance so I brought the part home not knowing if it would actually work. The first thing I did was shove the unit into a pot of almost-boiling water to see what it would read at the Mustang’s normal operating temperature.

38 Ohms! Very, very promising!!!

I then went down, drained the radiator again and installed the new, new temperature sending unit.

And finally, my long nightmare of a day with sending units came to an end:

At this point, I’m declaring gauge victory. I will eventually replace the fuel sending unit, but that can be done any time.

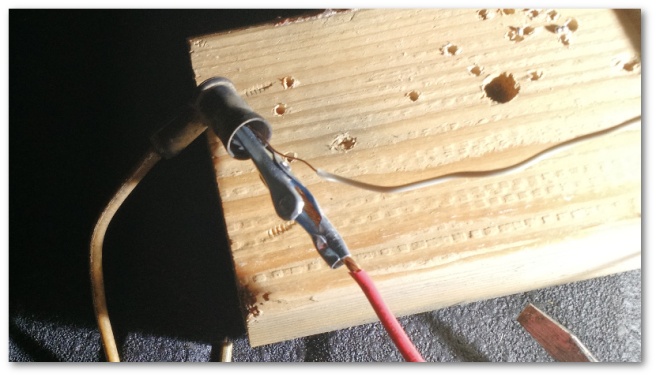

For what it’s worth, I also got the emergency flashers working today using the new wiring harness that allows me to reverse the polarity of the original socket.

Today’s original plan was to hook into this harness and wire up the choke and the radio. However, what I plan and what takes place…

You know the rest.