Sunday was a good day.

Today was better.

Today, the sun was out, the fog was gone…and oh, I got to watch my engine be born:

Gary at Speedy Automotive was especially awesome, spending the time to talk about what he was doing and why. We talked shop about cars and planes (he’s a pilot like my brother in law) and I had an awesome afternoon.

I found out the expected horsepower of the engine will be somewhere around 270-280 horsepower. This is up around 70 from the stock engine which is cool. I wasn’t looking for a racer so this is a nice bump without having the expense and maintenance of a super high output engine.

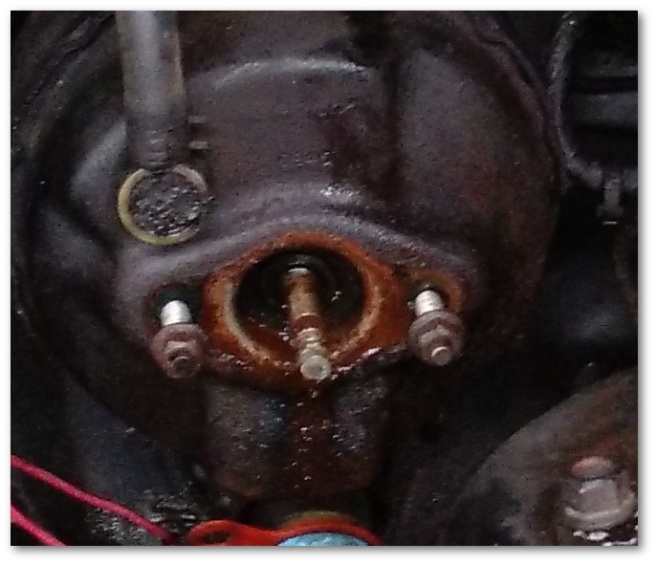

Here’s a shot of my newly machined heads with my freshly painted oil pan in the background:

I’m absolutely amazed at the level of detail that these guys have gone to as they’ve prepped the engine just to get to this stage. Here’s just a small summary of the things they’ve done:

- Measured each and every piston to a precision of ten-thousands of an inch.

- Bored and honed each and every cylinder to the exact size needed for the piston going into it. Each cylinder is fractionally different than the others to compensate for the manufacturing differences in the pistons.

- Custom bored each cylinder to correct for a previous seven degree difference between their angles to the crank shaft. All of the cylinders are now directly over the shaft.

And the list goes on. These guys are great.

Gary and team will continue working on the engine tomorrow and into early next week. It will be home soon.

In the mean time, I’ll keep looking at this carburative work of art:

and dreaming of the sound this engine will someday make when it’s home and installed.

Today was a good day indeed.